> Product > Screw chiller

Screw chiller

Based on extensive experience in technology

and reliabilityto the optimal level

Special features

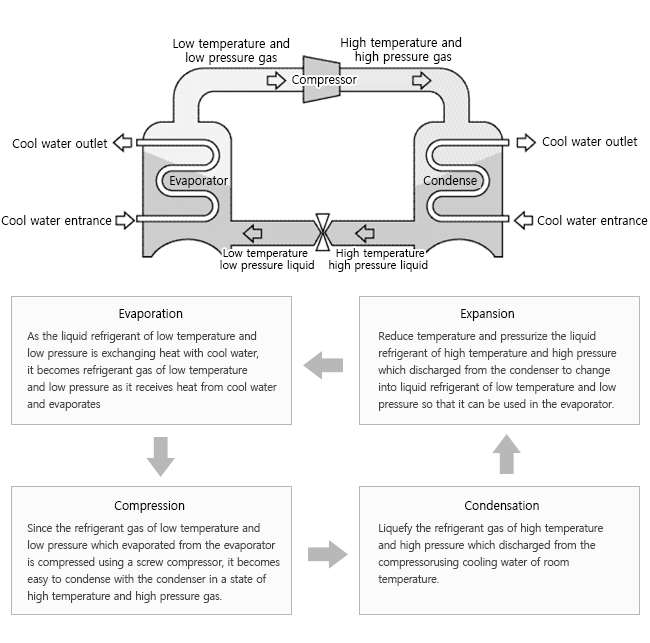

Refrigerant cycle

Refrigerant cycle

Reliability base on abundant technologies and experiences

Reliability base on abundant technologies and experiences

Excellence of Bumyang screw refrigerator is widely acknowledged abroad as well as in the

country. Innovative design and compact structure design ensures convenient installation and

maintenance, accumulated technical experiences and R&D increases product life span, and also,

reliable operation reduces operation cost and maintenance costs

Various scopes ranging 3 0 to700 USRT and compact structure design

Various scopes ranging 3 0 to700 USRT and compact structure design

Since Bumyang screw refrigerator is designed up to 700 USRT, the nation’s maximum volume for

single unit, its option for model is greatly expanded.This large volume single unit not only solves

inconvenience to use several

refrigerators combined for required capacity but also reduces initial

investment and installation coast, and since it has less inspection and maintenance areas and

parts, it has also additional advantages that its maintenance cost and time are saved

High performance steam extraction for maintaining a high-degree vacuum

High performance steam extraction for maintaining a high-degree vacuum

High performance automatic steam extraction device exert excellent steam extraction power

Convenient vacuum device to maintain high-degree vacuum

ISO 9001 Certification, verified quality management system

ISO 9001 Certification, verified quality management system

ISO 9001 certified Bumyang SW series screw refrigerators and compressors

guarantee consistent high quality. Through ISO 9001, the quality assurance programs are more

intensified and it is reconfirmed that quality assurance programs are operated based on a quality

system to meet international standard throughout all manufacturing and designing sectors for

SW SERIES refrigerators

Reliable performance through system and heat exchanger design based on

Reliable performance through system and heat exchanger design based on

thorough tests

Designing and selecting every accessory and part such as evaporator/ condenser heat transfer

tube and system such as compressors, evaporators, condensers, and expansion valves are

designed by thorough tests, based on strict development programs to meet mutual optimal

thermal equilibrium, exert reliable operation capacity as well as reduce operation coast through

coefficient of performance

Maximization of evaporator capacity and design for increasing lifespan at 0% By

Maximization of evaporator capacity and design for increasing lifespan at 0% By

pas rate

While baffle plates of existing evaporators has problem that cold water is bypassed through gaps

between cooling tubes, which lowers capacity of evaporators, applying the forming packing

attached Baffle Plat designed by Bumyang presents the fundamental solution for efficiency reduc-

tion of evaporators by realizing 0% By pass rate of cold water

Perfect compatibility, reinforced on-site service, rapid service support by profes-

Perfect compatibility, reinforced on-site service, rapid service support by profes-

sional technicians

Bumyang screw refrigerators have compatibility with each other. Thus, even though a product

itself is out of order, it guarantees convenient on-site after-sale service such as maintenance and

inspection, exchanging parts, and etc, and especially using semi closed typed screw compressors,

its on-site service is more intensified

Load related volume control, adopting high efficiency motor, design for minimum

Load related volume control, adopting high efficiency motor, design for minimum

power consumption

Through coordination between an electronic thermostat and solenoid valves of a compressor,

it is designed so that volume is regulated from 20% ~ 100% according to load, which suppresses

unnecessary power consumption to the maximum degree and ensures economical operation

through minimizing power consumption through applying high efficiency compressor motors and

rotors

Exercising exquisite control capacity through the MICOM controller with PLC

Exercising exquisite control capacity through the MICOM controller with PLC

function

Excellent control performance and high-classed design of Italy Karel Co., an international control-

ler maker, realizes quality satisfaction and superior special and strong points as below

Microcomputer controller combines PLC functionality with a sophisticated

Microcomputer controller combines PLC functionality with a sophisticated

control their own abilities

Italy World keonteurolreomeyikeoin Karel four outstanding control performance and achieve high

quality design, quality and satisfaction Has the following outstanding characteristics and merits.

- UL and CE Certification Mark acquisition

- Remote operation function and refrigerator R U N /Moss Point A R A L S-phase point

- Applying Precision control Algorithm by 0.01 unit through the PID control system

- Storing alarm history up to 300 events

- Basic built-in CAREL protocol and Modbus protocol for network connection

- Built in Auto Restart Operation function

- Adopting DIN Rail attachment method which is easily removable

Quiet operation without vibration

Quiet operation without vibration

Since inner motor and rotors of the compressor casing conduct only rotary movement, it has

considerably low vibration and the silencer in inner exhaust gas discharging tubes remarkably

reduces noise, which enables very quiet operation

Reliable operation of driving parts without trouble which improves the level of

Reliable operation of driving parts without trouble which improves the level of

screw compressors, ISO 9001 certification, hydraulic control valves

The compressor has a simple structure through using a screw compressor and does not require

separate operational electric motors, drive couplings, and oil separators, since major parts of an

operation unit are less and there are no absorption valves, discharging valves and etc as well as

such functions are built in, there are no abrasion or breakage of valves and operation parts, which

increases the life span of the compressor This compressor is entirely different from existing screw

compressor in the sense that it passed the compressor test to meet a high efficiency oil cartridge,

the 2 7 0 。direction change design of discharging gas, the specially designed high efficiency

refrigerating compressor motor, patented 5-6 asymmetric tooth typed high efficiency rotor

(EER3.2, U.S. Patent #5454701), the Fixed mill bearing (SKF, FAG), the Built in pressure lubrication

system, low vibration and low noise, and ISO 9007 JISB8606 Bumyang Series

products entirely has changed a paradigm of adoption and design of a screw chiller.

Perfect safety device

Perfect safety device

It uses a high/low pressure circuit breaker, an anti-freezer, an overload relay, a discharge high

temperature switch, an oil level switch, a safety valve, the crank case heater to prevent oil forming

and etc, so as to immediately stop a refrigerator in case of abnormal operation, which related

facilities as well as the refrigerator. In addition, it has perfect protective systems attached such as

the checking valve to prevent back ward flow of refrigerant and the Phase Error Relay to prevent

reverse turns of the compressor rotor

High Pressure Switch

In case where refrigerator is operated at high pressure exceeding designed pressure,

the operation circuit is shut off to stop its operation

Low Pressure Switch

Since in case where refrigerant is evaporated at low pressure less than a designed level, win-

ter-sowing of refrigerating tubes or motor burnt-out may happens, to prevent this, when evapo-

ration pressure falls below the set pressure, its operation is stopped

Safety valve/ Fusible Plug

In case where inner pressure of a condenser comes to exceed set pressure due to fire, abnormal

operation and etc, refrigerant gas is discharged out to prevent danger.

Compressor protection P T C

In case where motor coil temperature increases due to overload, overcurrent and etc, being

inserted in an inner motor of a compressor, operation is stopped to prevent motor bu rnt-out

Overcurrent Relay

In case where current of a compressor motor comes to exceed limited current, power circuit is

shut off to prevent motor burnt-out

Oil heater

During operation of a refrigerator is susoended, refrigerant mined with oil in an oil tank of a compressor is heated to prevent oil forming phenomenon and oil circulation of each part that undergoes friction is facilitated for smoothing lubrication

KITURAMI MACHINERY COMPANY

6, Poseunggongdan-ro 118beon-gil, Poseung-eup, Pyeongtaek-si, Gyeonggi-do, Korea

COPYRIGHTⓒ 2015 KITURAMI MACHINERY COMPANY. ALL RIGHTS RESERVED.