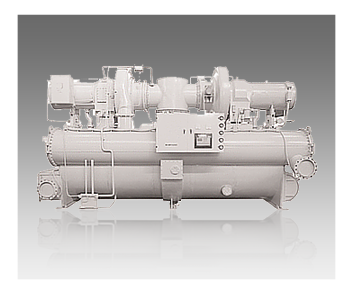

> Product > Centrifugal Chiller

Centrifugal chiller

Bumyang Centrifugal chiller upgrading perfor-

mance of the Centrifugal chiller which is well

known as its high reliability to a higher level.

Swingeing energy saving througg adopting high effciency a compressor and a motor

Swingeing energy saving througg adopting high effciency a compressor and a motor

Reduction in theoretical power consumption by the nucleate boiling pipe with excellent thermal

Reduction in theoretical power consumption by the nucleate boiling pipe with excellent thermal

performance and the Thermo Excel-C Tubo

Simple instrument with high reliability

Simple instrument with high reliability

Compact type with a reduced installation area

Compact type with a reduced installation area

Minimization of power for cooling water, water cooling pump Minimize loss of head,

Minimization of power for cooling water, water cooling pump Minimize loss of head,

Quiet operation with low vibration and noise

Quiet operation with low vibration and noise

Special features

In case of partial load, saving energy

In case of partial load, saving energy

Energy saving is achieved if load occurs when it is used most of the year as well as in case of

rating specification

Energy saving feature of HTDE type

Energy saving feature of HTDE type

Using 2 compressors, 2 condensers, and an evaporator, it is made of the piping system where

operation of one compressor is available

1. It has high efficiency desoite low load

It has good operation efficiency in low load, and capacity control is available in range from 100%

to 5%

2. Low starting current

Since compressor consecutivly start one by one, starting current comes to 1/2 of one unit typed

Performance features

Performance features

- Load interlocking capacity control operation is possible

- Individual type and multi-type (4Comp or less) are distinguished

- Silence operation with half-closed screw compressor

- Strong operation ability with optimum composition of freezing cycle

Compressor-It exerts excellent durability with its quiet operation

Compressor-It exerts excellent durability with its quiet operation

2 Cell unit-A condenser and an evaporator can be freely combined

2 Cell unit-A condenser and an evaporator can be freely combined

Since condensers and evaporators are separated, unit suitable for power consumption can be

easily provided based on the working condition

Decompression device-Excellent flow rate without on failure

Decompression device-Excellent flow rate without on failure

Since resistance to gas occurrence is increased and orifice which can regulate refrigerant flow, it

has the excellent flow feature in case of partial load as well as in case of rated operation.

In addition, since there is no operation unit, there is no fear of failure

Traction motor-equipped with protective devices for safety operation

Traction motor-equipped with protective devices for safety operation

Refrigerant cooling typed three phase induction motor using differential pressure during opera-

tion of refrigerators.

Including thermostat (directly inserted to coil) preventing coil overheating caused by lack of

cooling or humidity indicator detecting moisture intrusion, protective devices for overload, single

phase operation, zero voltage and etc are also equipped

Purge recovery unit-it can be operated even in case where refrigerators are

Purge recovery unit-it can be operated even in case where refrigerators are

stopped

The refrigerator is composed of reciprocating compressors, air-cooled condensers, and steam

extractors and since moisture and air are extracted into the air, it is efficiently operated all the

time

Lubrication System - High-performance lubrication device

Lubrication System - High-performance lubrication device

Refueling device is a forced lubrication system by trochoid pumps. Oil discharged from hydraulic

pump is sent to oil coolers, maintaining normal oil pressure by a control valve. Since a refrigerant

cooling system is adopted, this oil cooler never reduces performance such as boiler scale is

attached as the water cooled type. Integration of an oil tank and a gear room piping is shorten,

and contact locations are decreased and confidentiality is more increased at the same time. Since

the inner corner of a oil tank is smoothly finished, cleaning and oil exchange are convenient and

provision of clean lubricant is available all the time.

Terminals - how to handle a simple automatic operation jobs

Terminals - how to handle a simple automatic operation jobs

Through the built-in meter and control device displaying operation state such as start, stop and

etc, which are required fot refrigerators, it ensures highly simple handing

A disconnect switch, fuse, an electric circuit breaker and various secure devices and etc are

arranged in a compact mass within a box

Refrigerant-Non toxic and odorless refrigerant with high coefficient of

Refrigerant-Non toxic and odorless refrigerant with high coefficient of

performance and

Through adopting CFC-11, HCFC-123, it can be safely operated by anyone, regardless of refriger-

ator technical certificates

KITURAMI MACHINERY COMPANY

6, Poseunggongdan-ro 118beon-gil, Poseung-eup, Pyeongtaek-si, Gyeonggi-do, Korea

COPYRIGHTⓒ 2015 KITURAMI MACHINERY COMPANY. ALL RIGHTS RESERVED.